Introduction of Peanut Microwave Drying Machine

Microwave drying is an important and widely used food processing technology. It mainly uses the heating effect of microwave to increase the temperature, which causes water molecules to evaporate and achieve drying purpose. The heating process has the automatic balance ability. During the drying process, absorption of microwave power mainly depends on the dielectric loss. The dielectric loss of different substances is different. For example, the dielectric loss of water is larger than that of dried peanuts, so it absorbs more energy and the water evaporates quickly. Therefore, the microwave will not be effect dried peanuts, which prevents the dried peanuts from being burnt and overheating.

Features of Microwave Drying Machine

The microwave roasted peanuts are crispy and refreshing, with a strong flavor and a high swelling rate. Microwave processed peanuts can maintain their original color, and high-grade appearance quality improves market competitiveness.

Peanut microwave drying machine can be used to dry various materials. In food processing industry, it is widely used in baking and sterilization of peanuts, nuts, chestnuts, walnuts, almonds, broad beans, sesame seeds, sunflower seeds and other snack foods. Compared with traditional drying, the microwave-baked food is crispy and delicious, the product are puffed and full, the color is natural, the appearance is beautiful.

Peanut Microwave Drying Machine Advantages

Atmospheric peanut microwave drying machine use microwave heating under normal pressure. Compared with other drying machines, microwave drying has the following characteristics:

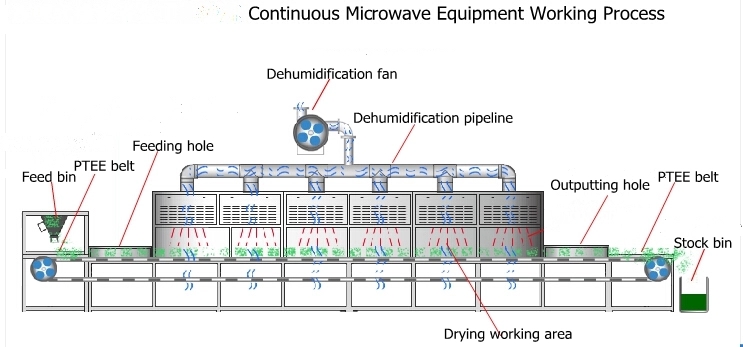

1. Both the microwave power and the speed of the conveyor can be adjusted steplessly. There is no thermal inertia. Microwave heating can quickly rise to required temperature, microwave drying machine can be started and stopped immediately. If provide fast drying speed for peanut, greatly save drying time. Microwave drying basically has no internal heat transfer phenomenon, It is a constant drying machine and the drying speed is extremely fast. Peanut microwave drying machine only takes 3-5 minutes to complete the drying process in peanut production line.

2. Peanut can be evenly heated and the product quality is good. During microwave heating and drying process, peanut can be dried from outside to inside, there is no temperature difference which may causes the peanut surface to harden and unevenly drying.

3. Peanut quality will not change after microwave drying process. Because the drying time is short, the characteristics and flavor of peanut can be maintained, and the loss of the ingredients of the nutritious food is extremely small.

Peanut flavor is more intense: microwave heating not only have better physical and chemical indicators than other methods, but also have higher volatile components, less loss of nutrients, and richer flavor.

The taste is better: the microwave heating puffing effect is obvious, and the water molecules inside the peanut are quickly vaporized to achieve the purpose of puffing.

4. Easy to control and operate. Traditional conventional heating takes a long time to reach the required temperature. Peanut microwave heating can quickly reach the required temperature. Operator can adjust the microwave heating power and drying temperature freely, what is more, peanut microwave drying machine is highly automation.

5. Microwave heating also has bactericidal effect. Microwave sterilization is performed under the dual effects of thermal and non-thermal effects of microwaves. Compared with conventional temperature sterilization, satisfactory sterilization can be achieved at a lower temperature and in a shorter time.

6. Improve production environment: microwave equipment has no residual heat radiation, no dust, no noise, no pollution, and it is easy to achieve food hygiene testing standards.

7. High thermal efficiency. Microwaves are reflected by metal, and pass through air, glass, plastic film, etc without being absorbed. Therefore, the heat loss of the strand is small, and the thermal efficiency is up to 80%.

8. The equipment occupies less space. The volume of the microwave heating equipment is also much smaller than that of the conventional drying machine.