Solutions

Pre-Treatment of Peanut for Peanut Butter Making

Peanuts need to be pre-processed in the production of oil, peanut butter and other deep processed peanut product. The pretreatment of peanuts mainly includes the storage, cleaning, grading, husking, drying, red skin removing, crushing, softening, rolling and steaming of peanut.

1. Storage

Peanut can be stored in the warehouse or in the open air. As long as the moisture content is controlled within 9% -10%. Peanut with moisture content above 15% will suffer frostbite if the temperature is too low. You must reduce the moisture content before storing . Peanut kernels should be stored in a dry, low temperature and sealed state, this way can prevent pest infection and the influence of external temperature and humidity, it is the general method to store peanuts.

2. Cleaning

The purpose of cleaning is to remove various impurities in raw peanuts, such as iron blocks, stones, soil blocks, plant stems and leaves, etc. The impurity content of raw peanuts after cleaning must not exceed 0.2%. We usually use peanut de-stoner in the process, The most widely used cleaning method include screening, air separation, magnetic separation, water separation, specific gravity stone removal and impact.

3. Grading

The purpose of the grading is to make the peanut size substantially uniform, and to ensure that the shelling and drying effects are uniform.

4. Shelling

Peanut shelling machine is the key equipment in this process, peanut must be shelled if you are making peanut butter. What is more, if you are making peanut oil, husking will improve the oil yield, improve the quality of crude oil and cakes, and facilitate the subsequent processes such as rolling embryos and the comprehensive use of skins.

5. Drying

Drying is to reduce the moisture of peanut kernels in order to remove the red skin. The presence of red skin has a significant impact on the color and flavor of peanut butter. After drying, the moisture content is reduced by less than 4%. In order to reduce the denaturation of the protein, the drying process must be under 60℃.

6. Roasting

Our peanut roaster can used electric heating and natural gas heating. The working temperature is controlled within the set temperature range. It is the most ideal equipment to roast granular food such as peanuts, seeds, almonds, walnuts, cashews, and grain crops. Features are high degree of automation, low noise, no pollution, high output, simple operation, etc.

7. Peanut Red Skin Removing

Peanut kernels are composed of red skin and kernels. Red skin is mainly fibrous tissue and hemostatin, while nutrients such as oil and protein in peanut are concentrated in the seed kernel. With our peanut peeling machine, red skin can be easily removed by the force of double-roller device. According to the specific gravity difference, air fan can seperate red skin and kernels.

Peanut Peeling Machine

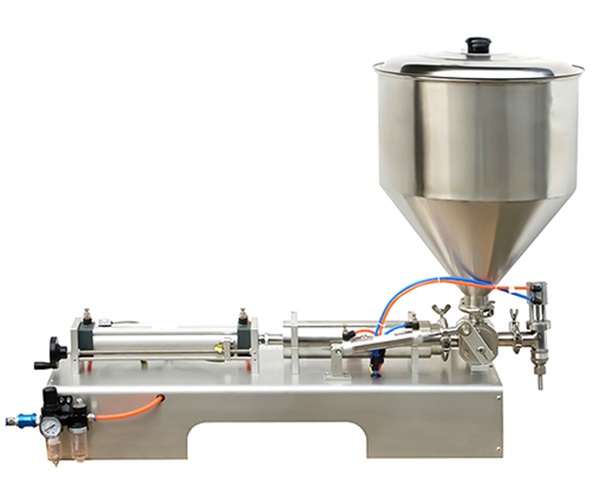

Peanut Butter Filling Machine