Structure of scraper peanut shelling Machine

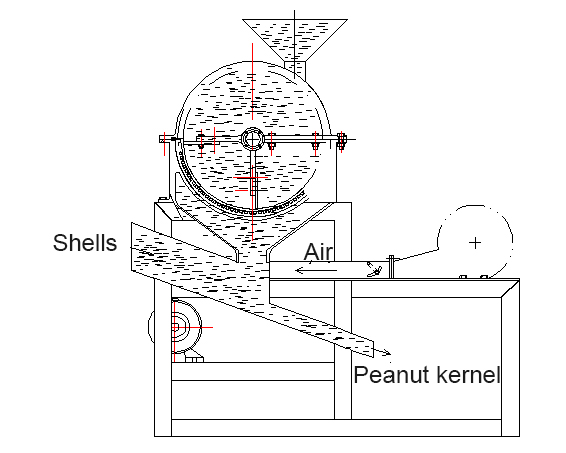

According to the shelling principle of the scraper peanut shelling machine, it can be known that the peanuts pass through the collecting hopper, shelling box, screen grid, lower box outlet, sorting port, and peanut kernel collecting bucket in order from top to bottom, so the design The basis for the overall structure of the sheller comes out.

The design process is from top to bottom, starting from the collection of peanuts. The top is the collecting hopper. Below the collecting hopper is the shelling chamber. The collecting hopper can be designed as a whole with the shelling chamber. In the peanut shell removing chamber, the peanut must be impacted and squeezed by the scraper to remove the shell. Therefore, the scraper is designed to be placed in the shelling chamber. After the peanuts are shelled by the impact and squeeze of the scraper, they must pass through the screen grid at the bottom, so the grid can be designed as a semi-circular grid cage and fixed in the lower half. After passing through the grid, the peanuts fall through the outlet at the bottom. During the falling process, a blower inlet is designed to separate the peanut shells from the peanut kernels. Blow away, and the lighter peanut shell will bring the airflow blown by the fan into the peanut shell collection channel, and the bottom of the channel is designed at a certain angle. The separated peanut kernels fall down and fall into the peanut kernel collection channel. This channel and the bottom surface of the peanut shell collection channel are designed as a whole. This design allows the peanut kernels blown away by the wind to roll back by its own weight.

Groundnut Shell Removing Machine

Scraper type peanut sheller is also called knife cage sheller, which is actually a combined device for peanut sheller and shell kernel separation. During shelling process, the shell of the peanut is broken by the squeezing and striking action of the scraper on the rotating shaft and the cage, and then the kernel is separated by the effect of wind selection. Its characteristics are simple structure and easy operation. It is mainly composed of feeding mechanism, peeling mechanism, kernel separation mechanism and transmission mechanism.

After the peanut enters the collecting hopper, it forms a uniform thin layer through the narrow inlet of the lower part and flows down into the shelling chamber. It collides with the high-speed rotating scraper. Under the hammer of the scraper, the peanut shell ruptures.. Part of the peanut did not collide with the scraper during the fall process, some collided without the peanut shell cracking. This part of the peanut fell onto the grid arranged by round steel rods. The distance between the diameters is not enough to accommodate a peanut nut, so the peanut will be hammered and squeezed again by the scraper while falling into the grid, so that the peanut shells are also crushed. After husking, the kernels and shells fall through the gap between the grids. At the same time they fall, they are affected by the adjusted air flow blown by the fan. The shells are sent to the collecting channel by the air flow due to the light weight, and the peanut kernels continue to fall because of its weight, so as to achieve the purpose of shell and kernel separation.