Application of Colloid Mill in Peanut Butter Production

Peanut butter is one of the foods processed by peanut butter machine, which is also known as colloid mill. However, many peanut butter products in the market will undergo solid-liquid separation after being placed for a period of time. Oil will float on the upper part, and solid peanu butter will sink on the bottom. As time goes by, the solid particles will become harder and harder, you have to stir the peanut butter to eat it. When making peanut butter, one of the most important requirements is to refine the granularity of the peanuts. The particles must be in the micrometer range to ensure the quality of the peanut butter, and it is not easy to appear “oil-evaporation” and other phenomena. The phenomenon of “oil separation” is mainly because the granularity of the peanut is not fine enough during the griding, which makes the oil and other ingredients such as protein, fiber, and hydrates insufficiently combined; there are some additives in the entire peanut butter system. And so on to enhance the stability of the entire system.

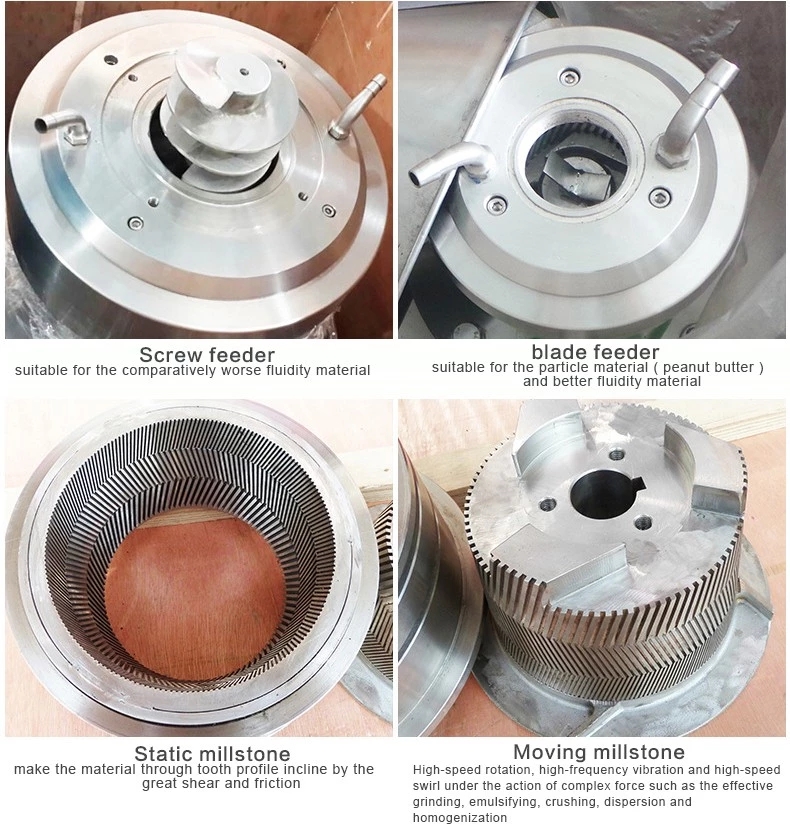

Colloid mills determine the peanut butter quality, mainly in the following aspects:

1. Rotation Speed

Most manufacturers produce colloid mills with a low rotation speed, resulting in insufficient grinding capacity of the equipment, and the particles of peanut butter are still very large. Peanut butter machine must has high roation speed and high shear force.

2. Structure of Grinding Head

The majority of colloidal grinding heads in China are twist-shaped, and the depth and width of the grooves in the grinding head are the same from top to bottom, so the grinding effect is very poor. With a good grinding head, the depth and width of the grooves in the grinding head are different from top to bottom. There is a layered sense from top to bottom, and the material can be refined step by step.

3. Mechanical Seal

The grinding capacity of the colloid mill depends to some extent on the speed of the equipment. The higher the speed, the higher the effect. However, the higher the speed, the greater the heat generation of the equipment, so high-quality equipment needs to be equipped with high-precision mechanical seals.

In this regard, we have realized very deeply in practice. The domestic colloid mill used in the past required a shutdown of 20 minutes for 1 hour, otherwise the mechanical seal could not stand. This is a headache and often affects production. Our peanut butter grinding colloid mill adopts German double-end mechanical seal and is equipped with a cooling system. In order to ensure the condition of cooling water, the equipment is stable for 24 hours and improves production efficiency