Make Peanut Milk With Peanut Grinder Machine

Peanut milk is rich in protein, fat, calcium, phosphorus, iron, zinc, manganese and other trace elements, vitamin E and various amino acids required by the human body, as well as unsaturated fatty acids, etc., to maintain human health, reduce tissue aging, and prevent Atherosclerosis has a good effect.Plant protein beverages are inherently “natural, green, nutritious, and healthy” in line with the beverage market development trends and trends. Plant protein beverages are likely to become the next round of beverage consumption hotspots and become mainstream products in the beverage market. Plant protein beverage market has huge development space and good development prospects.

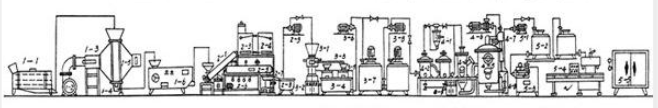

Peanut Milk Production Process Flow:

Peanut → screening → peanut roasting→ peanut peeling machine → soaking → peanut grinder machine → filtration → cooking → ingredients → homogenization → filling → sealing → sterilization → finished peanut milk

Peanut Selection. Choose full-grained, non-damaged, mildew-free peanut raw materials and get rid of impurities.

1. Roasting. Use peanut roasting machine to bake peanut at 130 ° C for 10 minutes to passivate the lipoxygenase in peanut kernels to prevent the fishy smell. At the same time, baking peanuts at high temperature is beneficial to peeling. It can also impart special flavor to peanut milk.

2. Peeling. Remove the peanut red skin to prevent the pigments and tannins on the peanut skin from attaching to the peanut kernel during the soaking process, so that the color of the peanut milk is deepened and the taste is astringent.

3. Soak. Use 8 times the weight of peanut kernels in water and add 0.5% sodium bicarbonate to soak at high temperature for 24 hours, so that the peanut kernels can absorb water and swell to increase the pulp yield.

4. Grinding. Peanut kernels are soaked in hot water at 70 ℃ -90 ℃ with 15 times the weight of dried peanut kernels, and then coarsely ground by a peanut grinder machine. The clearance of the peanut grinder is preferably 0.5mm. Then it is sent to the fine peanut butter grinder machine for fine grinding, so that the protein and oil in the tissue can be fully analyzed to ensure the uniform suspended particle size of the peanut pulp.

5. Filting. The ground peanuts were filtered through a 120 mesh filter cloth. At this time, the pH was 6.8 to 7.1.

6. Heating. The filtered peanut milk is heated and boiled. When the temperature reaches 80 ° C, the liquid surface will foam and boil, resulting in a lot of foam. At this time, part of the foam can be skimmed to ensure quality. When the temperature reaches 94 to 96 ° C, the liquid level is turned over and maintained for 1 to 2 minutes to achieve the purpose of sterilization. Be careful not to heat for too long, so as to avoid protein denaturation, layering and precipitation.

7. Ingredients. Peanut pulp 10% ~ 12%, sucrose 5% ~ 7%, appropriate amount of lactose, thickening agent 0.03%, emulsifier 0.4% ~ 0.5%, softened drinking water after filtering and sterilizing.

8. Boiling. The prepared peanut emulsion is pumped into a hot and cold modulation cylinder to heat and boil. When the temperature reaches 80°C, the liquid surface will foam and boil, resulting in a lot of foam. Some foam can be skimmed to ensure quality. When the temperature reaches 94 °Cto 96 °C, the liquid surface will roll over, and it can be maintained for 1 to 2 minutes. The pulp should not be boiled too long, protein precipitation and precipitation, which will cause layering.

9. Homogeneous. Process the well-mixed materials through a high-shear homogenizer to emulsify and homogenize them to make the material particles finer, and stratification and precipitation are not easy to occur.

10. Both the bottles and caps for filling must be sterilized first. After homogenization, when the temperature of the material liquid is higher than 80 °C, the bottles can be filled and sealed quickly and accurately.

11. Sterilization Put the sealed bottle into a high-pressure steam sterilizer. With a pressure of 1 kg / cm2, preheat to 80°C for 10 minutes, heat to 100 °C for 10 minutes, and then maintain a constant temperature of 121°C for 20 minutes. Use a air pump to reduce the temperature to 100 °Cand pull it out to cool to 50°C.