Introduction

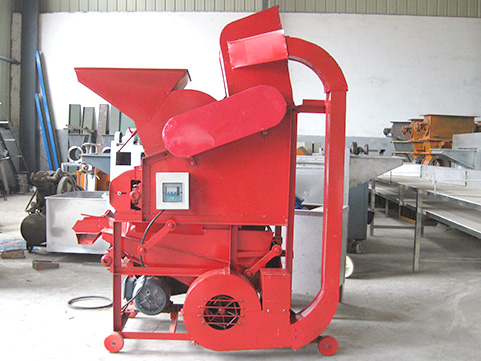

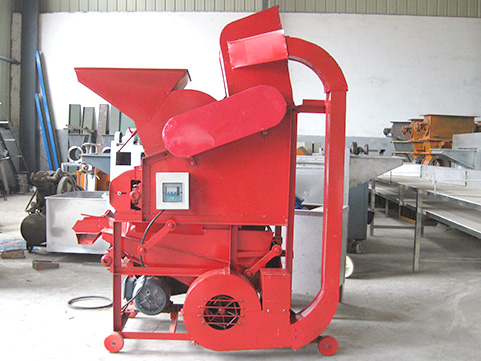

Peanut Shelling Machine

Peanut shelling machine has greatly improved production and peanut processing efficiency, and has promoted the development of the peanut processing industry. Due to peanut’s physiological characteristics, peanut shelling process cannot be combined with peanut field harvesting process, and shelling can only be carried out when the peanut contains proper moisture content. The peanut shelling process is to remove the shell of the peanut to obtain peanut kernels. The peanuts must not be too dry or too wet. If too dry, the peanut damage rate is high; if too wet, the shelling efficiency will be low.

Features

Groundnut Shelling Machine

In addition to pressing oil and making peanut butter, peanut can be deep processed to many peanut foods. Peanut raw materials are dehulled by a peanut shelling machine and remove red skin, cooking, and dried by far infrared and microwave. Deep-processed peanut products such as peanut powder made by refining, homogenizing, and spray drying after pre-cooking peanuts will definitely increase the added value of peanuts. Peanut shelling machine is a professional equipment which integrates peanut shelling and shell separation. The processed peanuts have low damage rate, clean separation, good color and less impurities.

Operating Instruction and Precautions

- Before start feeding peanut,operator shouldnot open the hopper until it is filled with peanut, then slowly open the feeder and close the discharge port at the same time. Operator should wait for the peanut kernel and small peanut to spread on the sieve surface and cover the layer about 20-30mm, then open the discharge port slowly so that the peanut kernels can flow out smoothly while the small peanut do not flow out. During the production process, the sluice gate should be adjusted to an appropriate position, otherwise it will increase the damage rate and reduce the cleanliness.

- During the shelling process, if the discharge port of peanut kernel are opened, but peanut kernels do not come out. You can adjust and lengthen the connecting screws, and the peanut kernels can be discharged smoothly.

- During the shelling process, if there are too many peanut kernels found in the shells, you should close the air inlet of the fan. If there are too many shell in the processed peanut, you should appropriately increase the air inlet of the fan.

- When the peanut shelling machine is working, the specific gravity sieve should be level flat, so that the impurity content of peanut kernels flowing out of the kernel mouth can meet the requirements.

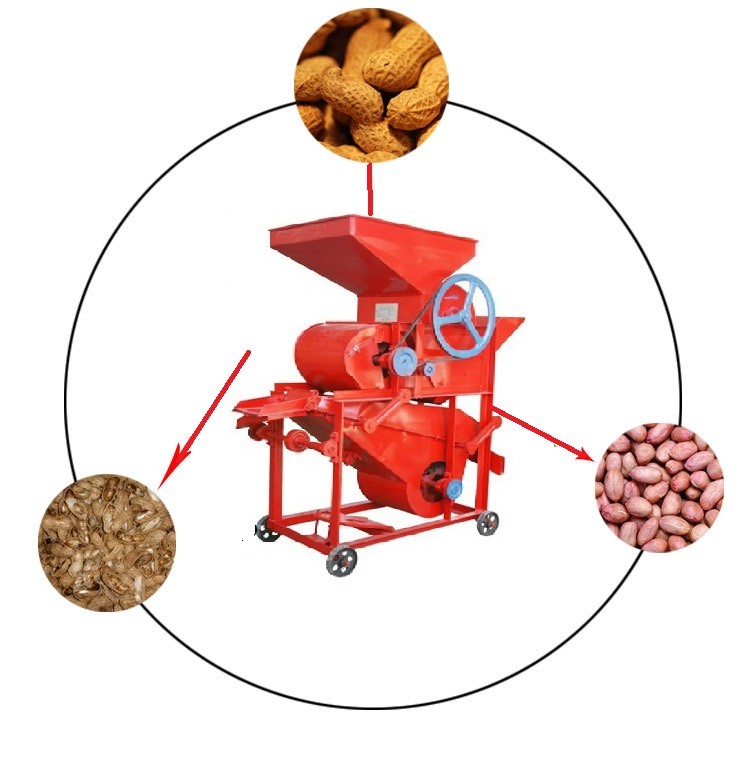

Peanut Shelling Machine Working Principle

The peanut shelling machine is composed of frame, air fan, rotors, single-phase motor, two sizes screens, feeding hopper, vibration sieving screen, V-belt wheel and transmission V-belt. After the machine started, the peanuts are put into the hopper in a quantitative, uniform and continuous manner. The peanut shells are broken under the constant impacts of the rotor, friction and collision. Peanut kernels and broken peanut shells pass through a sieve with a certain aperture under the rotating wind pressure and blow of the rotor. Peanut are shelled and pass a large size screen for the first time, light peanut shells are blown away, smaller peanuts are sieved and collected for a second time shelling. Peanut shells and grains are blown by the rotating fan, and the light-weight peanut shells are blown out of the machine. The peanut grains are screened by a shaker to achieve the purpose of selection. Then, the sorting surface goes down, flows into the lifting device through the returning port, and is sent to the rear drum by the air lifting device. The peeled peanut and shell fall through the rear arc grille, and are selected by the fan again. The specific gravity sorting sieve will further select qualified peanut and make sure all peanut are shelled.

Checking the Peanut Shelling Machine Before Use:

- Check whether the fasteners are tightened, the rotating parts are flexible, and whether there is lubricant in each bearing. The groundnut shelling machineshould be placed on a solid and stable ground.

- Check the power, the switch must be in the OFF position.

- After the motor starts, the rotation direction should be the same as the indicated on the implement. Run the machine for a few minutes and observe if there is any abnormal noise. When the operation is normal, the peanut can be fed evenlyin the shelling machine.

- Peanut should be fed evenly and in an appropriate amount. It should not contain iron filings, stones and other debris to prevent breaking the peanuts and causing mechanical accidents. When the peanut is covered with a sieve, the discharge outlet switch can be turned on.

- Peanuts should be at proper moisture condition. If it is too dry, the crushing rate will be high. If it is too wet, it will affect work efficiency. Select the appropriate screen according to the peanut size.

- When there are more peanut shells in the peanut, you can move the motor downwards to tighten the fan belt and increase the amount of air blow.

- Operator should away from the groundnut shelling machine while it is working, or else may be injured by belt drive.

- When stop using the shelling machine and store it, you should cleanthe external dust, dirt, and residual grains. The machine should be covered well and placed in a dry warehouse to avoid direct sunlight and rain. Belt should be removed and stored separately. Clean the bearings with diesel oil and dry them with butter. Transmission parts and the bearing chamber should be protected with sufficient oil.

Have More Question?