Peanut Butter Machine Operation Manual

I. Preparation Before Starting the Peanut Butter Machine

After the machine is installed and the power cord is connected, operator should follow the following instructions:

1. Whether the fastening bolts are tightened (the tightening rotor bolts are left-handed bolts).

2. Rotate the two fixing rods counterclockwise at the same time (release the locked fixing rod).

3. Rotate the adjusting ring counterclockwise by not less than 90 ° (the stator and rotor clearance should be increased).

4. Rotate the rotor with a special wrench and check whether the rotor is stuck. If found, do not allow to start.

5. Inching switch. Operator must check the rotation direction of the rotor, which should be the same as the direction of the arrow on the device (clockwise when viewed from the top).

Note: Incorrect steering may cause the rotor fastening bolts to loosen or fall off, and in serious cases may damage the machine. Check if there is noise or vibration when operating

6. Connect the inlet and outlet water tube as shown on the cooling water label on the device. The cooling water pipe can use plastic tubes.

Note: Incorrect connection of the inlet and outlet pipes will reduce the cooling effect.

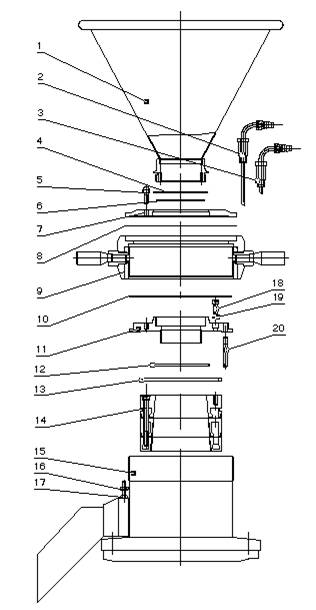

1. Hopper

2. Water inlet

3. Water outlet

4. O-ring

5. Cap screw

6. Seals gasket

7. Fixing ring

8. Seals gasket

9. Adjustment ring

10. Seal gasket

11. Stator bracket

12. O-ring

13. O-ring

14. Stator assembly

15. Peanut Butter Grinder body

16. Stop screw

17. Stop scree nut

18. Socket head cap screws

19. Spring washer

20. Guide pin

II. Production Operations of Peanut Butter Making Machine

1. Connect the cooling water. The cooling water pressure is about 0.15Mpa, and the water temperature is ≤25 ° C. Cooling water can be recycled after filtering.

Note: The small hole below the main body seat is an overflow hole. It is strictly forbidden to connect the cooling water or block it.

2. Turn on the motor. It is strictly prohibited to put in materials or other solvents before the equipment starts.

3. Adjust the machining clearance of the stator and rotor.

a. Rotate the two fixing levers counterclockwise at the same time (release the locked fixing lever).

b. Moving the fixed rod drives the adjustment ring to rotate and adjust the stator and rotor clearance. Turn the adjustment ring clockwise.

The gap between the stator and the rotor becomes smaller, and the granularity of the material becomes finer; when the adjusting ring rotates counterclockwise, the gap between the stator and the rotor becomes larger, and the granularity of the material becomes larger. The fixed ring is marked with a scale, and each time a small grid is adjusted, the fluctuation of the rotor clearance is 0.005mm. According to the fineness and output requirements of the processed materials, the best stator and rotor clearance is selected.

Note: The 0 bit is set when the device is shipped from the factory.

The clearance of the stator and rotor should be determined through tests according to the nature and fineness requirements of the processed materials. Clearance adjustment should be performed while the machine is running. Turn both fixing levers (locked fixing levers) clockwise at the same time.

Note: According to the production batch, you can use the limit screw to limit the rotation of the adjustment ring to reach the limit.

Determine the purpose of the rotor clearance. According to the use situation, the fineness of the processed materials should be checked regularly, and the stator and rotor clearance should be adjusted in time.

After replacing the stator and rotor, reset the 0 position and adjust the clearance.

4. Add peanuts for production and grinding.

Note: i. The equipment cannot process dry solid materials, only wet processing.

ii. The feed size should be less than 1mm. Materials should be cleared of debris before entering the equipment, iron and hard objects such as crushed stone particles enter the equipment to prevent damage to the machine.

iii. Depending on the nature of the material and the fineness of processing, one or more grindings can be performed.

5. Peanut Butter Machine Cleaning

Rotate the adjustment ring counterclockwise by not less than 90 ° (adjust the stator-rotor clearance). Add water to clean the machine.

Note: Equipment cleaning should be performed while the machine is running.