News & Technicals

Important Operating Procedures for Control of Peanut Butter Processing

1. Raw Peanut Inspection: Sensory inspection is performed on each batch of peanuts, and the surface quality of the peanuts is observed to see if there are mildew, mutation, and oily phenomena. Take the upper, middle, and lower samples of each bag, spread them out if necessary, and check their appearance. Check the species and make a moisture record.

2. Roasting: After preheating the peanut roasting machine for 10 minutes, put the peanuts in, set the temperature to be about 180-185 ℃, and the roasting time is about 20-25 minutes. During the roasting process, pay attention to the operation and peanut maturity. If abnormalities are found, shut down immediately. Sensory inspection of peanuts after roasting is completed, and the next process can be entered only after passing the inspection.

3. Peanut Butting Grinding: Put the peanuts into the peanut butter machine for grinding, perform the first salt grinding and coarse grinding, and grind peanut to a medium fineness of 100 mesh, then add stabilizers and related ingredient, and put them in the mixing tank , Heat the peanut butter to 100-110℃, mix well and sterilize at high temperature. Carry out the second peanut butter grinding and fine grinding, and grind it into 200 mesh fine and smooth creamy finished peanut butter.

4. Metal Detective: After cooling, the peanut butter products are detected every 2 hours to make sure no impurity is mixed in it.

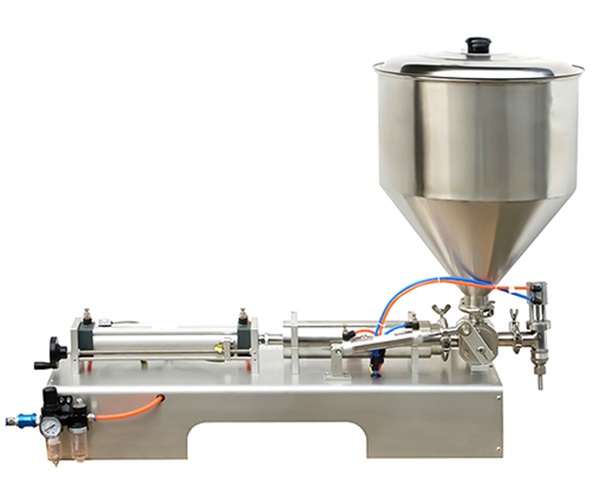

5. Filling and Package: Put the finished peanut butter into the package designated by the customer, quantitatively pack, Put the peanut butter into the package for weighing, and seal with a sealing machine after reaching the specified net content requirement. Disinfect the hands of the operators and the tools and instruments in contact with the product every day. At the end of the day, the packaging workshop should be cleaned up before leaving.

Peanut Machine

Peanut Butter Filling Machine

Automatic Peanut Butter Packing Machine

Peanut Butter Machine

Peanut Butter Production Line